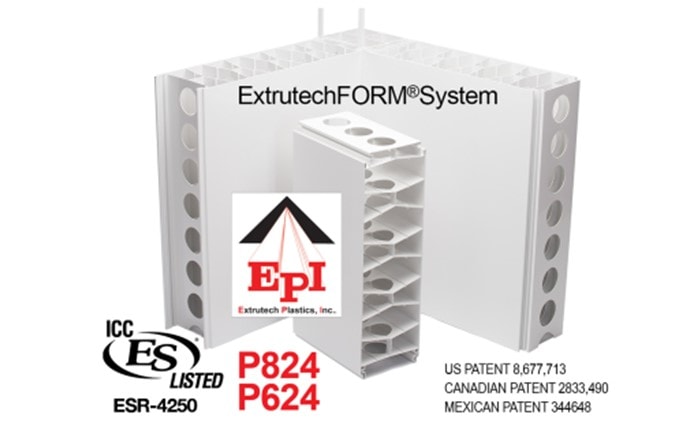

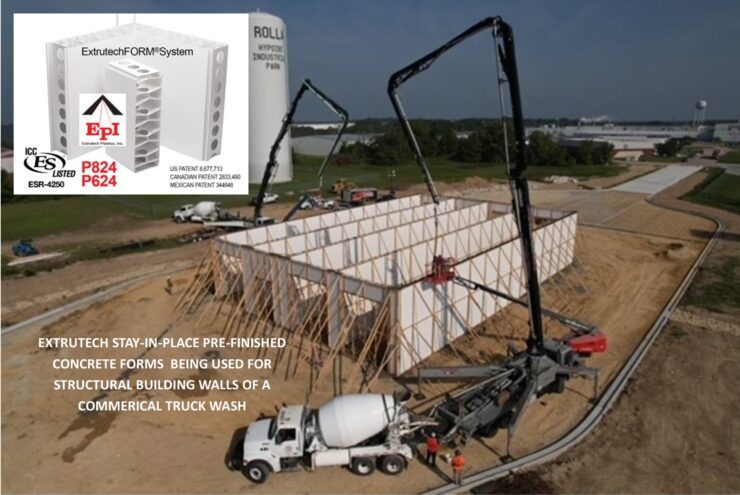

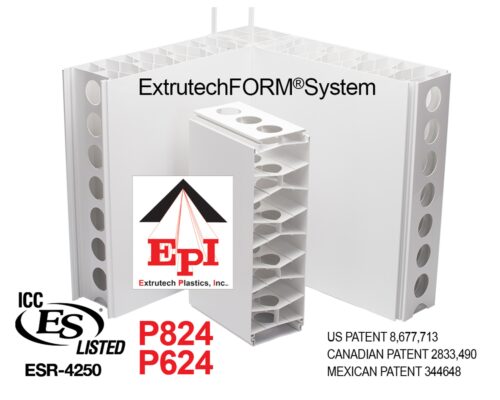

Extrutech’s Stay-in-Place Concrete Form Wall System offers a non-porous, prefinished structural concrete wall with a bright white surface on both sides, reducing finishing and installation time while providing an easy to clean solid structural wall. Available in 6” and 8” thick, two feet wide panels, and pre-cut panel lengths up to 20 feet long. Class A rating for smoke and flame, ICC ESR-4250 Listed, and Limited Lifetime Warranty. See additional details below and review the P824 and P624 FORM panels on our product specifications page. We also offer a good number of helpful video’s (Video Link) that provide more details on our products. We would be happy to help you with any questions you have, just Email or call 888-818-0118 us today, and let’s get your project going.

Extrutech Concrete FORM Panel Systems

Photo Gallery: ESR-4250 ICC-ES EVALUATION REPORT

Stay-in-Place Concrete Forms

For more than 32 years, Extrutech Plastics, Inc. has been a leading provider of wall and ceiling panels, stay-in-place concrete forms, partition wall panels, doors, shutters, and associated components. The patented Extrutech FORM Panel System is designed to provide an easily sanitized surface with a sleek aesthetic and exceptional durability. Ease of installation coupled with simplified cleaning and maintenance make Extrutech Plastics’ concrete forms ideal for a variety of industries and applications, including:

- Construction

- Food processing

- Agriculture

- Laboratories

- Cleanrooms

- Car washes

- Basements

Our concrete forms can be used in both indoor and outdoor settings. They provide a strong, reliable barrier that is resistant to environmental effects that cause deterioration and reduced service life in more traditional products.

About EPI’s Concrete FORM Panel System

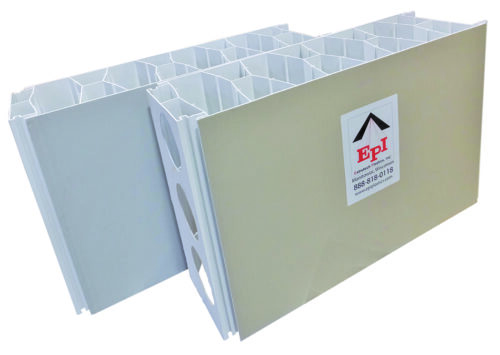

Extrutech Plastics’ FORM is a stay-in-place concrete form for 6 in. and 8 in. poured concrete walls. Each FORM panel is 2 foot wide, 6 inch or 8 inches thick, cut panel lengths of up to 24 feet long and shipped as a kit to your jobsite.

Our FORM System features include:

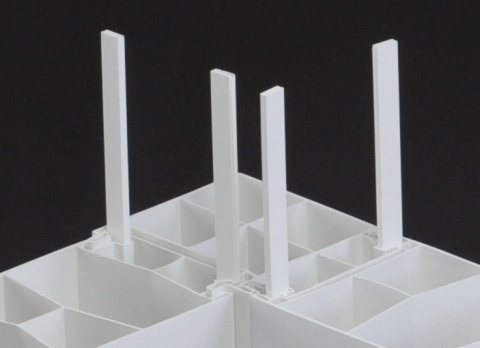

- A double-locking spline – (for strong non-leaking joints)

- Male/female interlocking joints – (for fast step-up and easier installation)

- Strong honeycomb interior walls – (for maximum panel stability)

- Protective peel-off film on both sides – (keeps panels clean during construction)

- Various curved angled sections are available for assembly of circular and curved wall structures

- Panels allow for vertical and horizontal rebar per your project requirements. (rebar is not supplied)

The Extrutech FORM panels lock together with a strong overlapping joint and use a double-spline E-Locking System that allows panels to be joined together without lifting one panel over another or sliding one panel down the edge of another. This unique locking system allows for exceptionally strong joints and quick installation. In addition, Extrutech offers custom-cut panel kits and panels lengths up to 24 ft. for an enhanced and seamless installation that is efficient.

Extrutech FORM panels exhibit a professional, finished appearance, with a variety of colors–including white, beige, and gray–that never need to be painted. The 2′-foot-wide panels exhibit fewer seams for a more streamlined appearance. Extrutech Plastics’ concrete forms offer a broad range of benefits over more traditional installations and other form systems, including:

- Water and corrosion-proof

- Low maintenance

- Panels will not rust, rot, or flake

- Resists mold, mildew, and bacteria growth

- Easy to clean with water and/or a mild cleaner

- Quick set up

- Protective peel-off film on both sides keeps panels clean during construction

- 15-year warranty

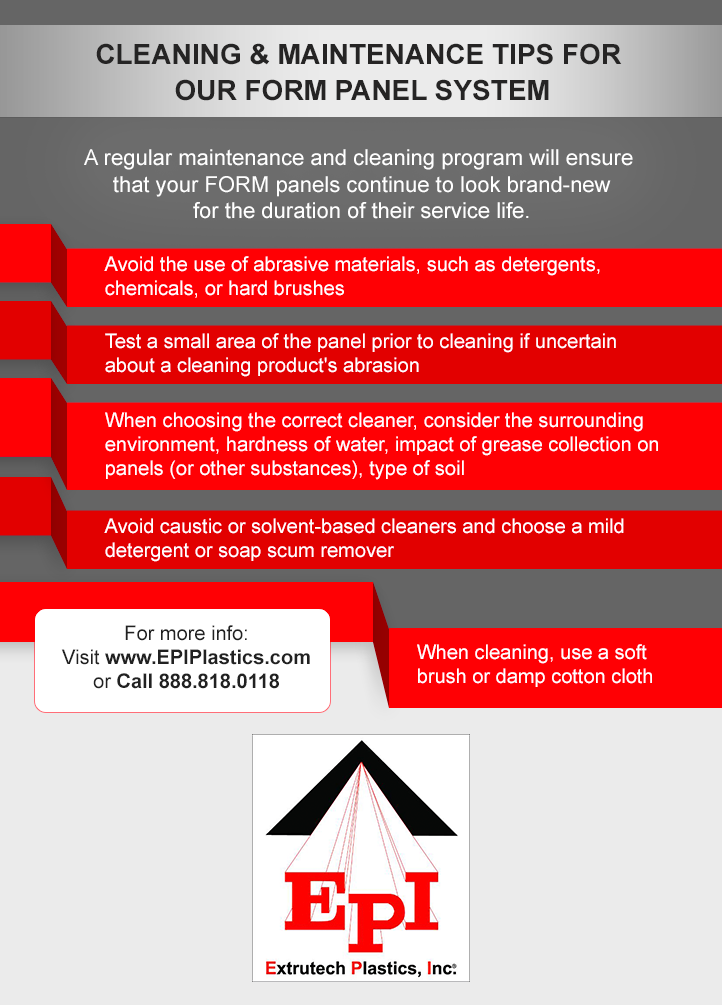

Cleaning & Maintenance Tips

Concrete wall forms are simple to clean and maintain. A regular maintenance and cleaning program will ensure that your panels continue to look brand-new for the duration of their service life.

Avoid the use of abrasive materials, such as detergents, chemicals, or hard brushes. If you are not sure whether something will abrade your panels, it is best to test a small area of the panel prior to cleaning. When choosing the correct cleaner, it is important to consider the following:

- Environment in which panels operate

- Hardness of water

- Whether grease or other materials may collect on the panel surface

- Soil type in the area

With a thorough understanding of the conditions to which the panels will be exposed, it will be easier to choose a cleaner that caters to your specific needs. Avoid caustic or solvent-based cleaners. Instead, choose a mild detergent or soap scum remover.

Regular maintenance is key to maintaining your concrete wall forms. Extrutech Plastics’ FORM panels are engineered with rigid, durable polymer that will retain its high gloss and original profile with adequate care. When cleaning, use a soft brush or damp cotton cloth. Panels can be treated using lime and soap scum removal products. However, be sure to test products that may be abrasive or corrosive.

For more heavy-duty cleaning and sterilization, low-pressure washers, low-heat water and steam cleaners can also be used.

Stay-In-Place Concrete Forms from Extrutech Plastics, Inc.

With exceptional ease of installation and even easier maintenance, Extrutech Plastics’ customizable stay-in-place concrete forms offer a versatile, cost-effective option. Our FORM panels are designed for reliability, long service life, and simplified sterilization. With more than 28 years of experience, Extrutech is dedicated to providing innovative, cost-effective solutions to meet our customers’ needs.

To learn more about our concrete wall forms and other products and services, contact us today or call 1.888.818.0118.

The Extrutech FORM System is listed under the following patents:

U.S. PATENT 8,677,713 CANADIAN PATENT 2833,490 MEXICAN PATENT 344648

ESR-4250 ICC-ES EVALUATION REPORT

ESL-1129 ICC-ES LISTING REPORT

ESL-1209 ICC-ES LISTING REPORT

Advantages:

- Quick Installation

- Never Needs Paint

- Fewer Seams – 2′ Wide Panels

- Custom Cut Panel Kits To 20′

- Snap Together Double Spline, E-Locking System

- Standard Rebar Reinforcing Methods Apply

- Water And Corrosion-Proof

- Cleans Easily – Low Maintenance

- Panels Will Not Rust, Rot, Or Flake

- Resists Mold, Mildew, Bacteria Growth

- Brightens The Interior Of Any Building

- Available In A Bright White, High Gloss Surface

- Low Maintenance, Easy-To-Clean, With Water/Mild Cleaner

- Protective Film On Both Sides Keeps Panels Clean During Construction

Recommended Use:

For any area that requires easy-to-clean concrete structural walls such as:

- Dairy Barns

- Cheese Plants

- Bottling Plants

- Milking Parlors

- Food Processing

- Cold Storage

- Car Washes

- Clean Rooms

- Laboratories

- Basements

LOAD TESTS & UPDATES:

P824 FORM Panel – E-72 Compression Test Report and E-72 Transverse Test Report

P624 & P824 FORM Panel – ESR-4250 Evaluation Report By ICC-ES

PRESS RELEASE 2018 – EXTRUTECH Announces Production Of FORM House

NEW PRODUCT _ EXTRUTECH FORM Housing Structures

NEW PRODUCT _ EXTRUTECH Torando Shelters Kits

HOW TO VIDEO: Extrutech Concrete FORM “HOW TO” Video

![]() Extrutech Step-By-Step Installation (PDF – 5.4MB)

Extrutech Step-By-Step Installation (PDF – 5.4MB)

![]() Extrutech FORM System Installation Guide (PDF – 254KB)

Extrutech FORM System Installation Guide (PDF – 254KB)

![]() Extrutech FORM Literature (PDF – 364KB)

Extrutech FORM Literature (PDF – 364KB)

![]() Extrutech FORM System – Specifications (PDF – 96KB)

Extrutech FORM System – Specifications (PDF – 96KB)

![]() 15 Year Warranty for White Panels (PDF – 79KB)

15 Year Warranty for White Panels (PDF – 79KB)

![]() Extrutech Form Panel Bracing Details (PDF – 348KB)

Extrutech Form Panel Bracing Details (PDF – 348KB)

![]() Cleaning and Maintenance Dec 2014 (PDF – 115KB)

Cleaning and Maintenance Dec 2014 (PDF – 115KB)

PANEL OPTIONS

Extrutech 8″ Inch Thick FORM Panel – Gives you the extra thickness for larger jobs

This concrete FORM panel is a large, tough, quick setup panel, with snap together edges that form a strong, straight, flat, pre-finished wall, greatly reducing your setup and finishing time. Each 8″ thick by 24″ inches wide panel can be cut to the inch to lengths up to 20′ long or pre-cut to project specifications for windows and doors; and shipped as a kit to your jobsite. For more information on this system Contact one of our salespeople for more details, pricing and options.

Extrutech FORM Panel Color Options are now available on the P824 two foot wide, 8″ thick FORM panel

Extrutech Plastics has added a color option to the 8″ thick stay-in-place concrete form panels. The colors are added during the manufacturing process to one side of the panels. This color option allows you to have white panels on the interior of your structure and beige or gray on the exterior, as shown here on the samples. For more information on this option contact one of your salespeople for more information.

EXTERIOR OPTIONS

EXTERIOR THIN BRICK OPTIONS

Sample photos of thin wall faux brick applied directory to the surface of the panel, you can find a large number of patterns, sizes, and colors available on the market with individual panel sizes to cover large areas quickly. Please review all products and do a sample test before, using on a large area.

EXTRUTECH FORM PANEL LOCKING

The Extrutech FORM panels lock together with a overlapping joint and use a double spline E-Locking System that allows the panel to be joint together side by side, without having to lift one panel over the other or slide one panel down the edge of another. Extrutech FORM Corner Detail locked together with the double spline E-Locking System.

Note: Two spline inserts are required at each joint.

Extrutech FORM Panels

shown on standard footing with horizontal and vertical bracing.

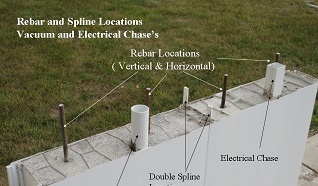

Two Extrutech FORM Panels

with rebar double spline, vacuum, and electrical chase.

Extrutech FORM Panels

on standard footing with required rebar as per design.

Extrutech FORM Panels

shown on standard footing with horizontal and vertical bracing.

Extrutech FORM System

shown on standard footing with required horizontal and vertical bracing.

Extrutech FORM System

shown on standard footing with support bracing during construction.