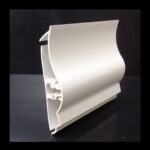

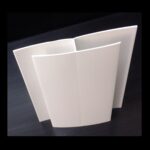

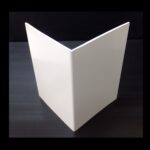

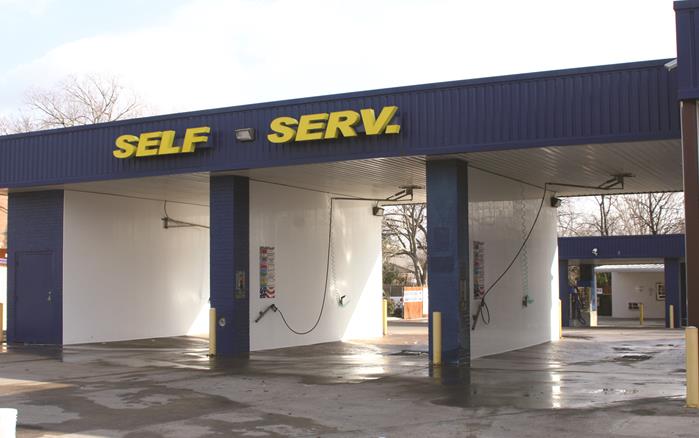

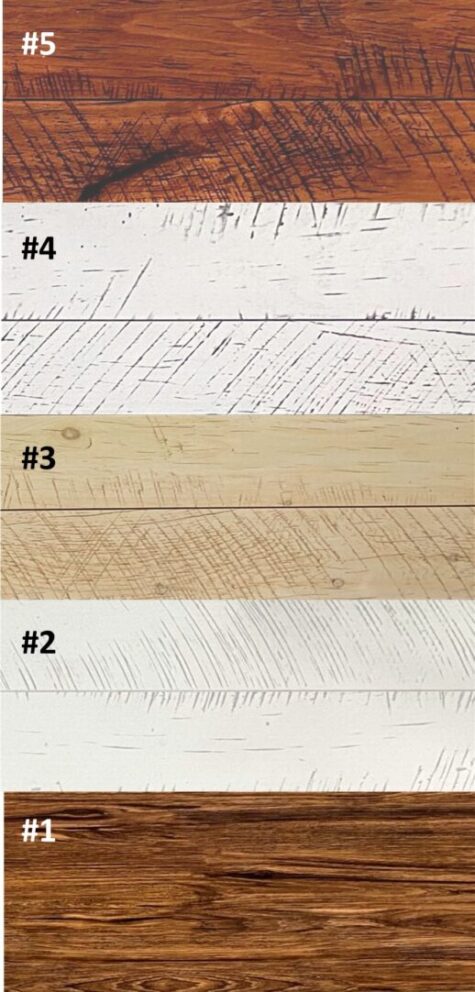

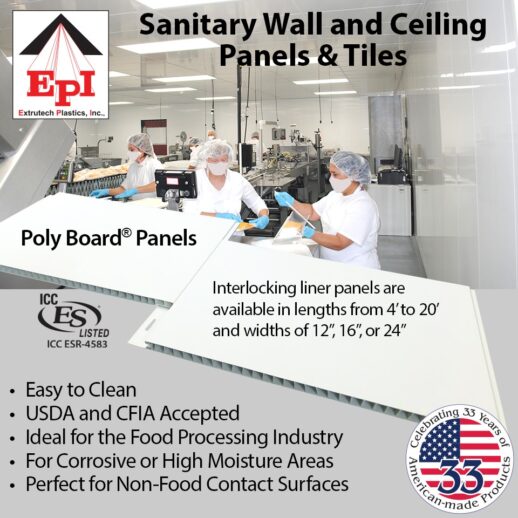

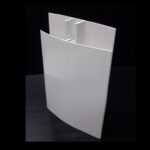

Extrutech PVC Wall and Ceiling Panels. Since founded in 1992, Extrutech Plastics, Inc. (EPI) has developed a reputation as a leader in the production of PVC Wall and Ceiling Liner Panels. Extrutech (Poly Board) PVC Wall and Ceiling Panels are manufactured in Manitowoc, Wisconsin. Using only American sourced raw material known for its quality for our exterior-food grade PVC Panels. EPI (Poly Board) panels are available in three different widths: 12” W (P1300), 16” W (P1600), and 24” W (P2400). They have a smooth and reflective surface suitable for improving light quality within a space. Panels are 1/2″ thick and available from 4’ – 20’ feet lengths, cut to the inch, for less waste. We have a wide array of accompanying trims which run at 8’ – 16’ lengths. The 12″ (P1300) panel is available in several colors as show below, with custom color services are also available.

Extrutech (Poly Board) panels have a tongue-and-groove design – the hidden nailing fin along one side allows for fast and easy installation, with no visible fasteners. The panels closed-cell structure prevents water absorption, making it moisture, mildew and mold resistance, ideal for the food service industry and environments with high moisture, salt, or acidic content. See our installation video below for step-by-step installation or click here to view. Email or call us at 888.818.0118 today for a quote or for any questions you have on our PVC Wall and Ceiling Panel System.

.

.  .

.

.

.

. .

. .