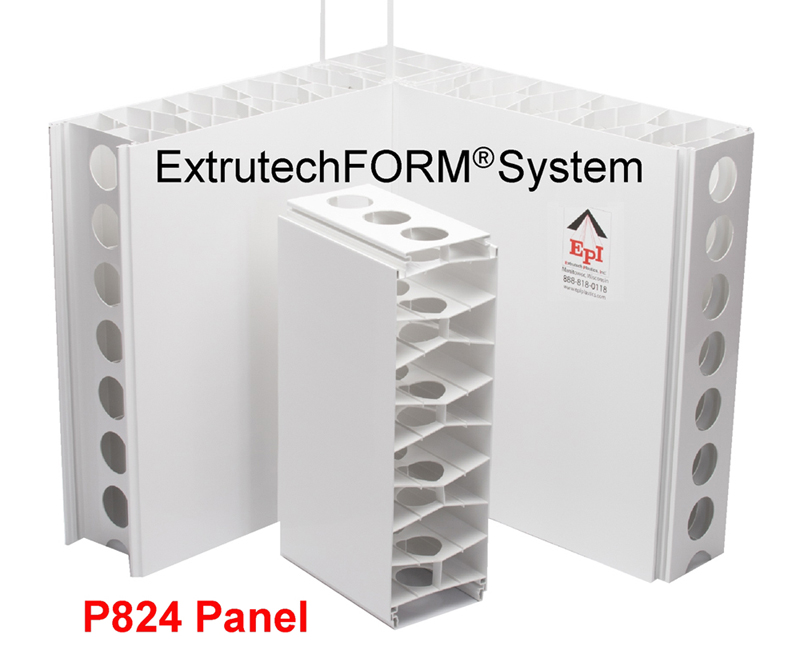

6″ and 8″ Thick

How wide are your panels?

24″ Wide

Do your panels lock together?

Yes, with two locking splines per joint

Do you have a corner piece?

Yes

Can you make odd panel sizes?

Yes, from 2-1/2″ to 24″ widths

Can you handle different angles?

Yes, we can make almost any angle.

What colors are available?

White, Beige and Light Gray

How long do you make the panels?

We can make the panels up to 20’ long in one inch increments.

Do I have to lift these panels overhead to slide together?

No, only high enough to get over the rebar in the footing.

How do they go together?

They snap together by pressing the male end into the female end or vice versa.

Do the panels come pre-cut?

We make the panels to your order, pre-cut to your drawing in a kit form.

How long does it take for an order of panels?

Usually in four (4) weeks depending on the size of the job.

Can you insulate the panels?

You can insulate the inside or the outside of the panels

What is the R-Value?

Insulation inside = R-23. Insulation outside = R-12.

What is the concrete form made out of?

Rigid, virgin exterior PVC with NO regrind.

How strong is the concrete form?

It is very strong and can hold 4000 PSI concrete mix with proper bracing.

What type of concrete can I use with this form?

Use a good 4000 PSI concrete mix with pea gravel and a slump of 4 to 5

How do I fill the forms?

Depending on the height of the ground you will need to hire a conveyor or pumper truck to fill the forms.

What about cold weather construction with this form?

The form and concrete mix should not freeze so warm your wall area to prevent freezing and use a cold weather concrete mix with plasticiser additive. Warm wall area to minimum 40 degrees or preferably 50-60 degrees.

What procedure should we use to pour the concrete in the forms?

You should brace the walls appropriately first, then starting from the end, pour the concrete 2-3’ high layers, reversing direction each time you reach the end of the wall, constantly pounding with a rubber hammer to settle the concrete in the form. Weave back and forth until the wall form is full of concrete.

Can I vibrate the concrete in these forms?

Yes you can.

How do I brace this form?

Secure 2×4 to the footing on both sides of the Form to hold the bottom of the panel in place. Then use 2×4’s connected across the top of the FORM with a metal strap to hold the top of the wall steady. Use vertical 2×4’s, every 6’ along the wall with a horizontal 2×4 attached every 4-6’ from bottom to top of wall as illustrated in the directions. DO NOT SCREW ANY OF THE 2×4’s TO THE FORM!

Can you add rebar to this form?

You can add rebar to the form in the vertical and horizontal direction just like any other concrete wall form. Use short corner sections at the corners and overlap the corresponding rebar from either direction. The rebar can lay in the center of the form at the bottom of every fourth circle cut out. Overlap the rebar according to ACI 318.05 and ACI 318.11. Consult your local engineer for the proper rebar specifications and follow recommendations.

Can you put screws into this panel?

No you should not do that.

What tools do I need to put this together?

Here is a list of tools: rubber hammer, tape measure, adjustable clamps, and a 4’ to 6’ level. Also need a regular hammer, nails and stakes to secure the bracing. Turn buckles are nice to have to level the wall easily to the eve line string

How are the panels delivered to the jobsite?

The concrete FORM panels come on a pallet with ten (10) panels per. The panels are shrink wrapped and banded to the pallet. The FORM panels also come with a peel off film that is applied to each side of the panels. Peel this off after all the construction work is completed.

How do I know where the panels go on my job?

We provide a drawing showing where each panel is to be located. Each panel comes with an individual label at the bottom of the panel to indicate where the panel belongs.

What is the warranty on these forms?

10 years.

Where are the panels made?

In Manitowoc, Wisconsin

How long has Extrutech been in business?

22 years, started in January 1992

How do I get a quote for my job?

Send your plans to Extrutech Plastics. We will do a take off and prepare an accurate material list and provide you a cost for the proper material.

Who is responsible for the proper bracing and support of the forms before the actual pouring of the concrete?

The construction company is responsible to follow the proper procedures outlined by Extrutech and the American Concrete Institute, ACI – 318.5,.11. Extrutech assumes no liability in the construction methods of any building contractor.

How do I attach the roof system to the top of this wall?

You will place threaded anchor bolts in the top layer of concrete allowing the bolts to stick out of the concrete about 2-1/2″. Then you can mount a 2×6 plate to the top of the wall, drill holes and bolt the wood down to the top of the wall. Now you are ready to toe nail your roof trusses to that plate and complete the roof framing.

Where does this type of product work well?

Many areas such as: Car and truck washes, Dairy parlors, Poultry farms, Hog facilities, Fish plants, Food Processing plants, Cold storage, Laboratories, Coolers, Dog kennels, Retaining walls, Clean rooms, Basements, Storm shelters, Aquatic tanks, etc.

Where can I purchase this product?

You may purchase this product through an extensive list of qualified Design – Build Contractors and Commercial Builders Nationwide. Call our office for references or more information.

Why should I buy this product?

The Extrutech FORM is a water proof, custom made, stay-in-place form. It is easy to assemble and brace. Fewer seams every 24″. High quality virgin pvc compound with no regrind. Walls are easy to clean and maintain. Made in America, in Manitowoc, Wisconsin.